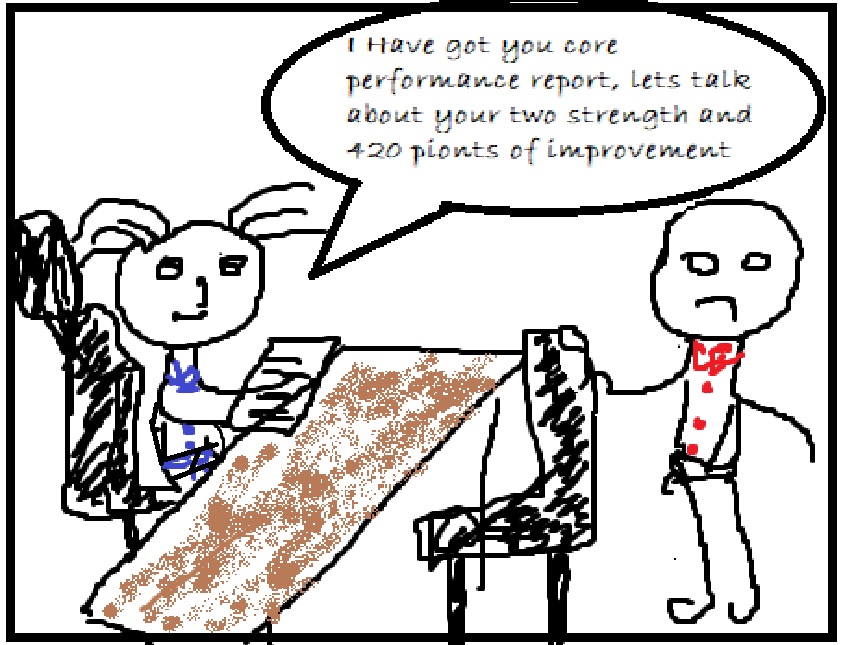

“Appraisal time is going on. Today is the day, technie X is having one on one meeting with the manager. The most proficient PCB design engineer in the group is all set to ask for increment.

X will ask bluntly, oh, so fed up of useless office politics.

it’s time. <War drums> this is in X’s mind.

tik-tok… tik-tok… tik-tok… One our passed… technie X is out of the cabin.

Burning with revenge…… more revenge…… <Dramatic Bollywood music> oh that music is also in his mind.

technie X is all set. now X will engineer to fail the PCB, but shhhhh…. no one knows <ta ta da>

or can someone figure it out 😉“

On a funny note, this is the time to make them pay. Really? Oh, this article can be taken as both ways, as a revenge 😮 or a guideline for what not to do. The decision is purely up-to reader. Technie X has decided, clues from personality should be used to model into design decisions. The engineering to doom the PCB design begins with instructions to the subordinates.

Faster is better

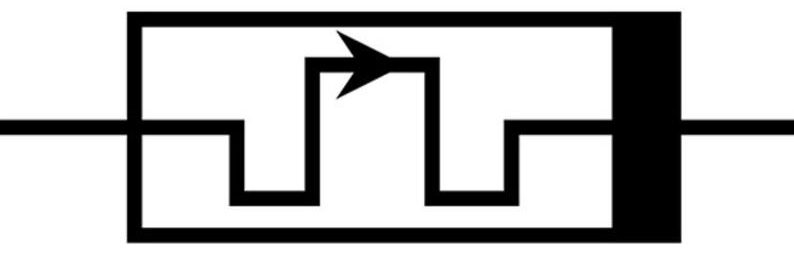

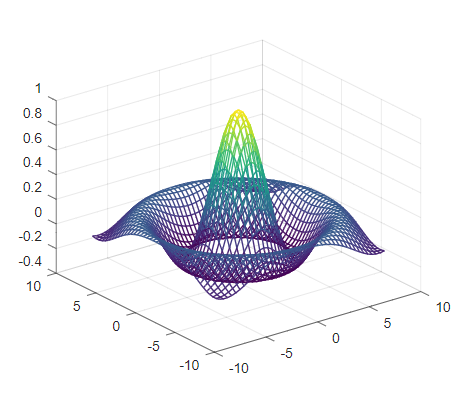

- No matter what the design is, choose the fastest clock with the highest rise time possible. Harmonics of this will surely develop some great relationship with the neighbourhood. Selection of clock should be so fine, that even with nano-second time division, CRO should show a perfect square.

- Choose the components with the highest slew rates. Slow is boring. The signal shape should be perfectly square always.

Be a wanderer

- Travelling is very important. Take your time to layout the longest possible ring road all around the PCB. Make sure to show the edges of the board to the clock. Some sightseeing is necessary. And if you are feeling adventurous why not give some zig-zag with sharpest turns and jump between layers along the path.

- Do you like jumping signals? I wish you could jump to save time. But this flexibility can be given to your all-time friend “electronic signal”. Make sure it has all the fun, it jumps across potentials, other signal and also isolated planes.

Cost cutting is necessary

- Make sure to remove unnecessary copper from planes. Cutting the weight is good, isn’t it? It will save cost also. This will also help the currents to flow from longer paths. Give them the long route to drive everything crazy.

- What is that unnecessary copy-paste decoupling capacitors are doing here. Save some cost remove all but one. Now it is better. PCB looks clutter free too.

Be radiant

- You want to be radiant. Aren’t you? So should be your board it should be detected from far. Start with the AC input. Put the power regulators far from the entry point. at least give it some space to show its glory.

- Mind the privacy of I/O cables. Keep them apart. Only then they can show their true potential to radiate. Keep the filters away if any.

Style is everything

- Why not paint the metal enclosure with this non-conductive matte finish. Any left spot can start corrosion, cover it all.

- Keep the ground away from enclosure. One doesn’t need unnecessary connections coming to pretty cover.

After all this even if the design works 🙁 and company plans to sell it. Oh well, come to techniex. Our PCB design guideline series will surely help.

- 6 Steps of verification for error-free schematic

- 100 Point checklist for schematic design

- Selecting a PCB stack-up for EMC compliance

- Strategy for component placement

- Decoupling – Path to power integrity

- 15 PCB Layout guidelines to achieve EMC requirements

- 4 steps to review the PCB layout

- Checklist for error-free optimized PCB layout

- Engineered to doom – Red flags for PCB design

- Board bring up: Giving life to the design